PTFE-Based TruTech Materials

Custom and Modified PTFE Materials

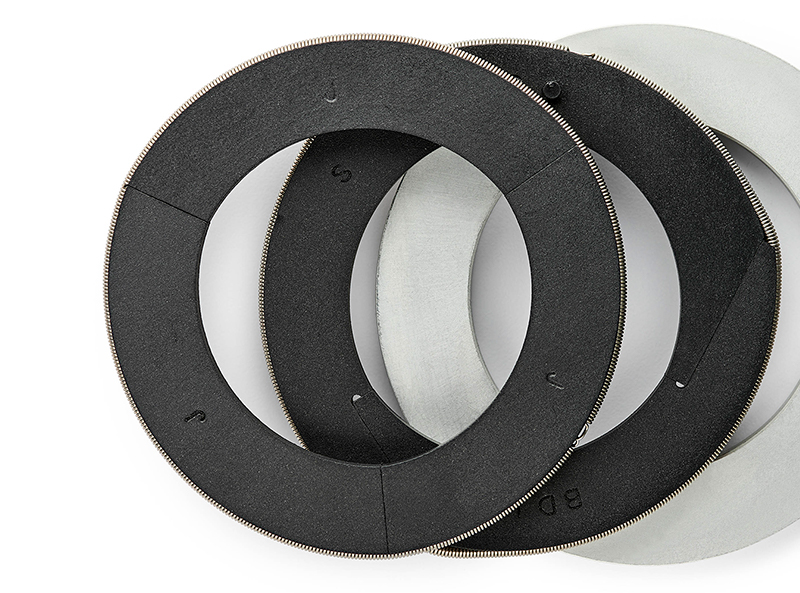

PTFE (polytetrafluoroethylene) materials are the most common type of material used in reciprocating compressor piston, rider and packing rings. The TruTech® materials line from Cook Compression includes custom PTFE and modified PTFE materials that provided superior durability and optimum performance characteristics for your application.

PTFE Material Properties

Due to its unique molecular arrangement, PTFE has an extremely low coefficient of friction. In addition, it is non-reactive with most common gases and liquids and has excellent chemical resistance.

It can be continuously used at temperatures up to 250°C (490°F) and works well at extremely low (cryogenic) temperatures.

Reinforcing fillers, wear resistant additives and self-lubricating fillers are typically applied to enhance the properties of PTFE. Fillers are selected and combined to reduce wear and improve performance based on the specific operating environment.

Material Grades Tailored to Operating Requirements

Depending on compressor lubrication, gas composition, temperature and other operating conditions, Cook Compression may propose PTFE materials of standard, upgrade or specialty grade. For specific material properties, please reference the TruTech materials catalog.

Standard PTFE Materials

Standard grade PTFE materials, using fillers such as glass fiber, MoS2, graphite or carbon, provide good friction, wear and mechanical properties in lubricated and low severity non-lubricated service. TruTech standard PTFE materials include:

- P1110

- P1120

- P1130

- P1140

- P1150

- P1160

- P1170

- P1210

- P1220

Upgrade PTFE Materials

For more challenging conditions – higher temperatures, higher pressures and/or harsh chemicals – Cook Compression typically specifies upgraded PTFE material variants. TruTech upgrade PTFE materials include:

- P2210

- P2220

- P2410

- P2420

- P2430

- P2510

Specialty PTFE Materials

Bone-dry non-lubricated service, problem gases and other niche applications use specialty PTFEs with premium fillers, propriety formulations and propriety processing methods. TruTech materials in this class include:

- P3200

- P3300

- P3310

- P3320

- P3330

More from Our TruTech Line

PEEK Materials

Generally stronger than PTFE materials, PEEK materials are the second most common type of material for piston, rider and packing rings. They may also be specified for valve components in high-temperature environments.

PPS and Polyimide Materials

Cook Compression produces specialty PPS and polyimide materials as well. PPS has broad chemical resistance. Polyimides are suitable for extreme, high-temperature applications and are resistant to most chemicals.

Complete In-house Processing Capabilities

Material compounding, compression molding and machining are all performed in-house and are closely monitored to ensure the quality and consistency of finished products.