Research & Development

Compressor Innovation and Product Development

Cook Compression is committed to ongoing innovation and product development to advance reciprocating compressor performance and capabilities for our customers, in both new and developing applications.

Through customer partnerships and industry monitoring, we identify and develop proprietary products and technologies that have practical application in the deployment of state-of-the-art machinery.

Innovation Lab and New Product Development

The Dover Precision Components Innovation Lab provides world-class testing capabilities to test and validate new products, materials and processes under real-life conditions.

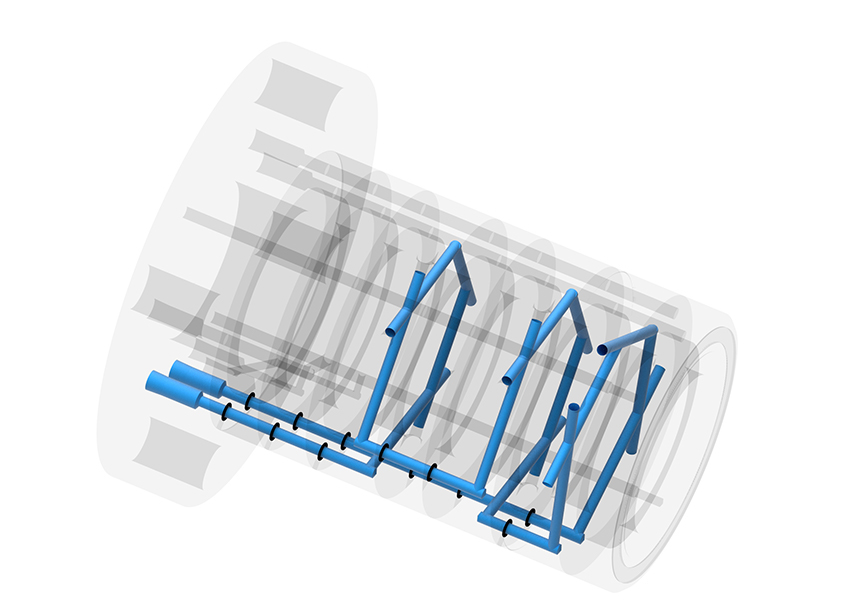

Located next to our Houston manufacturing facility, the Innovation Lab features a large, two-stroke reciprocating compressor; a small, high-speed reciprocating compressor frame, as well as special test set-ups and component level test rigs to measure:

- Valve flow dynamics, performance parameters and leakage rates

- Impact resiliency of materials for valve plates and sealing elements

- Wear resistance of piston and rod ring materials

- Component life and performance

Advanced Materials Development

The Dover Precision Components Materials Technology program integrates materials research with our engineering expertise and practical experience in reciprocating compressor operation.

At our Materials Laboratory, a dedicated team of materials scientists works to develop next-generation polymeric materials, as well as optimize process parameters, enhance product quality and perform failure analysis.

State-of-the-art mechanical, chemical, optical and thermal analysis equipment, as well as advanced friction and wear testing is used to identify, differentiate and evaluate materials by their signature properties, such as filler ratios and composition, mechanical performance over a wide temperature and frequency range, mechanical and thermal characteristics, and transition points.

New materials receive intensive laboratory analysis and undergo comprehensive testing before release to the field.

A Team of Experts

Dover Precision Components development engineers take an interdisciplinary approach, contributing expertise across products lines and specialties. We develop innovative solutions to advance performance in even the most demanding applications, be it high temperatures or high loads, challenging speeds or pressures, corrosive environments, or difficult lubricants and supply.

In partnership with our customers, we apply our technological expertise to create more reliable, more efficient equipment.

A Heritage of Innovation

Cook Compression carries on the legacy of its founder – inventor C. Lee Cook. In 1888, Cook introduced the first metallic packing for piston rods in locomotives and steamships. In 1923, he brought in a metallurgist to help improve the product. To this day, we continue to combine design advances and materials development to deliver durability and performance.

Talk to Our Experts

To discuss development opportunities with our engineers, reach out to us today.