Case Study

New Technology Aids Non-Lube Conversion

A petrochemical company in Perm, Russia, was experiencing severe problems and high costs in maintaining the filtration/separator phase of their process after compression. The trouble revolved around a hydrogen compressor that had originally been installed with lubricated cylinders and packing cases. Lube oil leaking from the compressor was contaminating expensive filters, causing them to malfunction and requiring costly maintenance.

This compressor (along with a second six-cylinder hydrogen compressor) was consuming 22,000 liters (5,812 gal) of oil per year. Worse still, the operator estimated that existing cylinder ring and packing designs could run continuously for only 4,000 hours on the 2nd stage cylinders before experiencing failure due to wear.

Conversion to Non-lubricated Service

Cook Compression was asked to assess the possibility of converting the hydrogen compressor from lubricated to non-lubricated service. A Cook design team from the Ellesmere Port, U.K., facility reviewed key parameters of the application:

- 100 bar at 105°C on the final stage

- 71% hydrogen +27% carbon monoxide gas mixture

- High speed of 5 m/s

Following a thorough analysis, the team recommended the following design changes:

- Manufacture seal rings in the packing case and cylinder with TruTech® P3330 material, which was specially developed for non-lube, dry gas applications

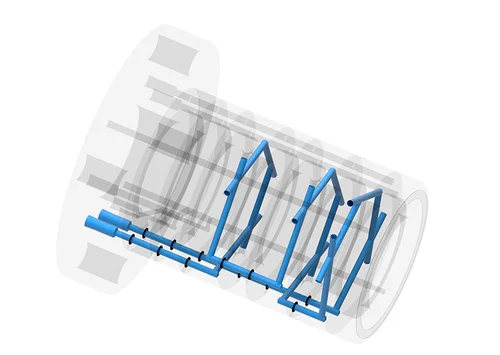

- Introduce Vortex Cooling® cups into the packing case

- Install Cook’s exclusive Solid Ring technology for all seal rings in the packing case

- Replace existing wiper rings with patented Cook RTV® wiper packing

- Equip with high-performance MOPPET® compressor valves for increased reliability and ease of maintenance

A Successful Outcome

All Cook recommendations were carried out on the compressor. The RTV wiper packing eliminated oil leakage from the crankcase. This prevents contamination of the seal rings in the pressure packing case – a vital requirement for non-lube conversions.

Cook Solid Ring technology allowed a reduced number of sealing elements in the packing case. With fewer seal rings and Vortex Cooling cups, compressor rod temperatures have been maintained at roughly 50°C (122°F), an excellent result for a non-lube application.

The conversion has eliminated process contamination and excessive oil consumption associated with this compressor. The compressor has also continued to run trouble-free for over two years. The customer is so satisfied with the results that plans are underway to equip a second, six-cylinder machine with Cook Compression non-lube conversion solutions.

Related Case Study

Redesign Extends Run Time for Hydrogen Chloride Compressor

On a non-lubricated three-stage compressor in France, rapid ring and packing wear was causing a reduction in machine throughput. As part of a comprehensive solution, Cook Compression recommended modifications to the piston and rider ring styles on all three stage of the tandem piston.