COOK CLEAN Sealing Systems

Comprehensive Emissions Solutions

COOK CLEAN® sealing systems are designed for reciprocating compressor owners and operators who want to exceed emission regulations, maximize natural gas recovery, increase compressor efficiency and reduce downtime and maintenance costs.

Although leakage can be minimized by properly specifying and maintaining the packing case, rings, and rod, the fundamental design of reciprocating compressors makes gas leakage practically unavoidable. Therefore, some type of barrier must be employed to prevent emissions from escaping into the atmosphere.

COOK CLEAN, with its high performance and flexible range of design options, is the industry leader in low-emission sealing systems.

Reduce Fugitive Emissions To Near-Zero Levels

A leading compressor OEM has documented leakage rates near zero to 0.75 SCFM per throw when comparing a COOK CLEAN uncut seal ring (BTUU/CUU) technology against traditional packing technologies, both in controlled R&D environments and from field data.

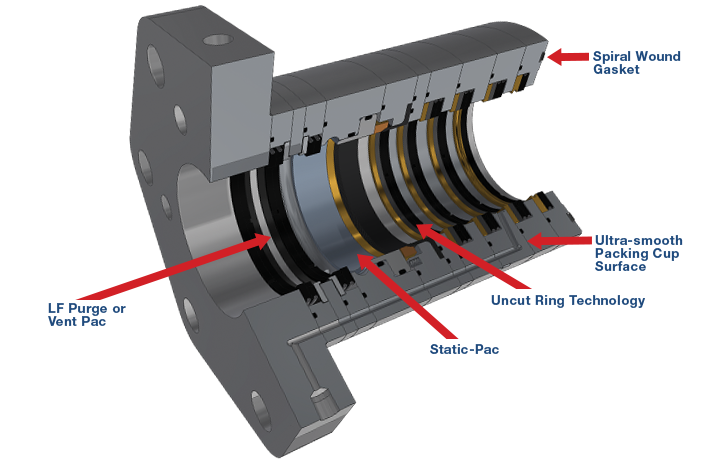

Features for Superior Sealing Performance

- Spiral-wound end cup gasket made of a highly conformable composite stainless steel/nonmetallic material creates a superior seal between the packing case and compressor.

- Low emission uncut, or solid, ring technology (BTUU® or BTRR™) features a gapless design that eliminates leakage paths.

- Ultra-smooth lapped sealing surfaces for all rod rings provide excellent surface-to-surface contact for a tight seal.

- LF Purge Pac® or LF Vent Pac® assemblies use our patented Low Friction technology to extend seal life and simplify maintenance.

- Recent design enhancements extend the run time of the packing set and provide extra protection to prevent debris from entering the gas vent.

Advantages

- Reduces fugitive emissions to near zero levels

- Offers easy, economical conversion for most compressors

- Provides an effective seal, minimizing purge gas consumption

- Optional monitoring system allows predictive maintenance

Near-Zero Emissions for Net-Zero Goals

Presented by Craig Martin, Chief Engineer, Rings and Packing Products; Michael Pratte, Engineering Team Lead; Scott Riefer, Business Development Manager; and CompressorTech2 magazine.

As the regulatory landscape evolves towards more stringent emission requirements, compressor manufacturers, owners, and operators seek reliable solutions to help them comply with government mandates and corporate ESG goals. Cook Compression developed the COOK CLEAN® Sealing System, which lowers fugitive emissions to near-zero levels, to address these concerns. Watch our webinar to learn more.

Related Case Studies

Stringent Emission Requirements? Not a Problem for COOK CLEAN

COOK CLEAN® Sealing System Upgrade Exceeds Required Run Times

COOK CLEAN in the News

Targeting Fugitive Emissions in Gas Compressors